The knife is known as one of the most popular kitchen tools. But knives are not only a kitchen tool. It is used for hunting, fishing & camping as well. That was the basic information about types of knives that everyone knows. But there are some other exciting things about knives that everyone should know.

Do you know the components, material & types of knives you use every day in your kitchen, hunting, fishing & during your camping? I am sure that every person doesn’t know about these basic things about knives.

So, today in this article, we will describe knife components, knife manufacturing material & knives classifications. Just keep reading.

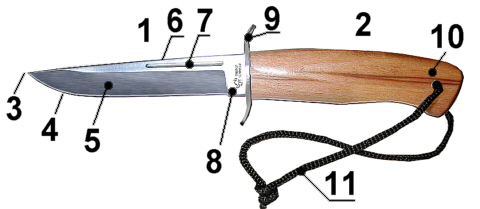

Components Of The Knife

- The knife consists of a blade and a handle.

- If the blade converges to its end in a wedge-shaped manner at one point, then this point is called the edge of the blade.

- The sharpened side of the blade is called the blade or cutting edge.

- The blade can be smooth (plain) or sawtooth (a serrated knife, serrated). The surface of the part of the blade tapering to the edge is called descents.

- The side opposite to the blade is called the butt of the knife.

- Sometimes grooves are made on the lateral surface (holy men) of the blade.

- The unsharpened part of the blade adjacent to the handle is called the fifth blade.

- Sometimes between the blade and the hilt, there is a guard which protects the hand.

- The part of the blade inside the handle, and to which the handle is attached somehow, is called the blade shank.

- The part of the handle from the side of the palm and butt of the blade is called the back; the opposite position from the side of the edge is called the belly of the handle.

- Sometimes a hole is made in the head of the handle, into which a lanyard is passed.

Materials Used In The Manufacture Types Of Knives

Currently, knife blades are often made from carbon or alloy steel, which undergoes special thermomechanical treatment. Hardness, wear resistance, impact strength, corrosion resistance are the main properties that the steel of any blade should have.

However, there are soft materials and products for which the use of steel blades is counterproductive. For them, it is better to use knives made of soft metals (annealed iron, copper).

For example, it is more convenient to cut hot bread with just such a thin knife with an uneven cutting surface. Such a knife is easily dull, but it is also easily and quickly put into working condition. The handles use wood (or bark for lightness), metal, leather, rubber, and synthetic materials.

Making Of Knife

Making of Knife takes a lot of tedious work. We shall look at the various steps in order of the making. It has about ten steps:

Step One: Laser Cutting

Laser cutting is also known as fine banking. This process involves cutting the blade out of raw steel, either a plate or coil. The Plate stock is usually for making more extensive and thicker knives that need thicker and harder blades. Recent manufacturers use computer lasers for cutting blades out of plates.

The blade made of the coil is usually thinner. The process of cutting steel out of the coil is called fine banking.

Step Two: Rough Grinding

After cutting, both sides of the blade are then grounded to get the right thickness. This is what we call Computer Numerically Controlled machining.

Step Three: Stamping

The stamping is done based on the model or types of knives. This might involve inscribing special features such as a nail notch. The model, manufacturer name are marked at this point.

Step Four: Heat Treating

Heat treating is the next step in the process, and this process involves using heat to treat the blades so that they can be suitable for their end-users. This process helps the hardness, strength, and flexibility. The process does not affect the chemical composition of the knife.

The heat treating involves a different method that depends on the steel types and the types of knives to be made. Whatever the style or steel to be used, it involves three processes. First, The blade is to be treated at hyper-high temperature and then cooled. They are then slowly heated to a very high temperature.

Step Five: Close Tolerance Grinding

After the steel has been heated and treated, the next thing is to take it through a process of tolerance grinding to give it a consistent thickness. This grinding is done using the CNC machining we talked of earlier.

Step Six: Blade Finish

This is done to make the knife achieve a shiny finish. It also helps to smoothen the mark made during the grinding process.

Step Seven: Hollow Grinding

The next step is the hollow grinding process through the computer machine to get the right shape and the proper slope from the top to the cutting edge at the bottom. It helps to retain its sharpness.

Step Eight: Assembly

In this step, the blade is coupled with all the other materials, fasteners, adhesives, and other components depending on the type to be made.

Step Nine: Edging And Sharpening

The edge is done individually; they are finish-edged by hand on a sharpening wheel. The edging helps to retain the border and for sharpening later on.

Step Ten: Cleaning

The last step is when it is clean before it is then packaged.

Classification Of Knives

Knives can vary in purpose and design.

By designation

Weapon

- Combat knives are designed to defeat the enemy in the course of hostilities and special operations. Sometimes tactical knives are distinguished separately (including folding ones); such a name allows for their use as combat knives.

- self-defense knives

- Throwing knives are a special kind of throwing weapon or sports throwing projectiles.

Tourism, hunting, and fishing

- Hunting knives – a large group of blades used in hunting may include varieties such as a game knife, skinner knife, camp knife, etc.

- Fishing knives. Gutting and cutting fish and auxiliary operations during fishing impose additional conditions on the design of the blade; one of the characteristic fishing knives is a fillet knife with a non-slip handle.

- Tourist knives – a group of heterogeneous knives, united by the possibility of being used in nature.

- Machete knives for cutting branches, undergrowth, reeds, etc.

- Survival knives – knives with a set of tools and accessories (usually placed in a hollow handle) for survival in extreme conditions.

Universal

- Everyday knives or EDC knives (from the English Everyday Carry – to wear every day) are relatively light and easy-to-wear knives, adapted for various activities (from household to self-defense).

- Multitool – universal folding knives with a large number of tools.

- Stationery knife. It is a thin replaceable blade with slots for “breaking” inside a plastic holder.

Kitchen and dining rooms

- Kitchen knives – a large group of blades designed for cooking. There are fruit, potatoes, sirloin, bread knives, cheese knives, butter knives, etc.

- Table knives – included in the cutlery together with a fork and spoon.

Other

- Special knives – knives designed for any particular activity, for example, surgical knives, boning knives, diving knives, etc.

By design

- Non-folding knives – knives in which the blade and the handle are fixedly connected.

- Folding knives – knives in which, in the inoperative position, the blade is hidden in the handle. There are automatic ones among the folding knives, in which the edge is brought into working class by the force of a cocked spring or by another mechanism, and inertial ones, in which the opening is made by rotating the hand holding the knife.

A separate type of folding knife is the so-called—gravity knife, in which the blade is brought into working position by gravity. The presence or absence of the blade retainer in the open state is also taken into account. Locking knives are classified according to the type of lock: liner-lock, back-lock, axis-lock, etc.

- Knives with removable (replaceable) blades.

Final Thoughts

So, how was your reading? I hope this will be helpful to know all basic things about knives like; components, material & types of knives.